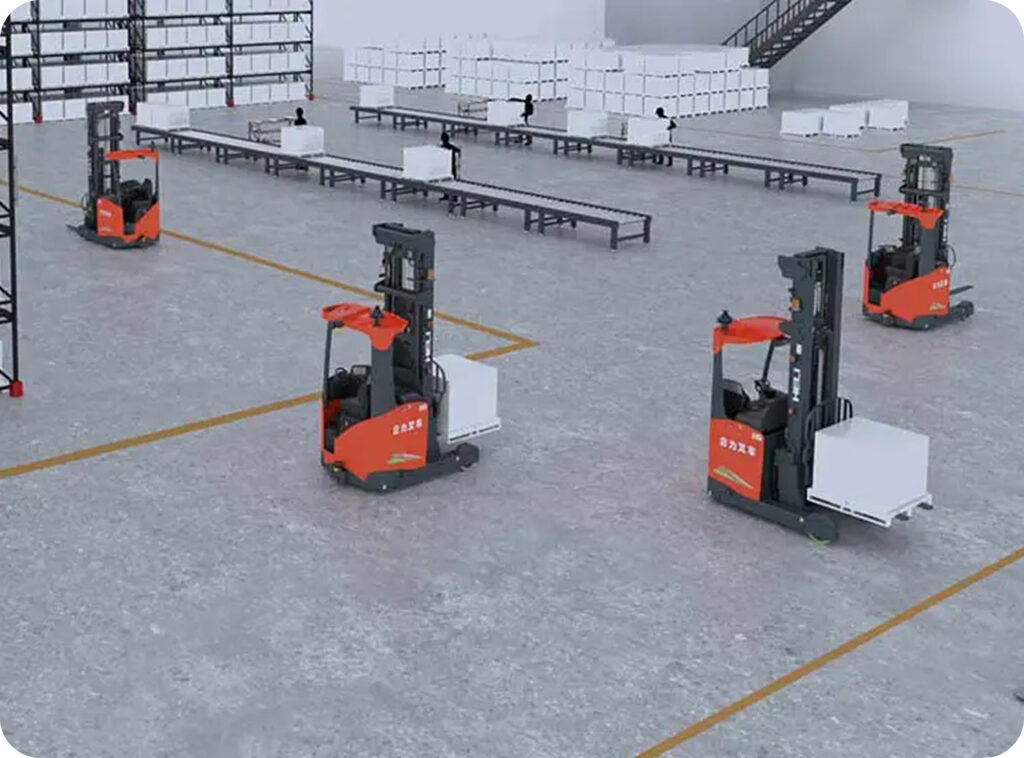

Commonly used for the transfer of heavy cargo.

- Wide legs can be customized for smooth handling of heavy goods;

- The AGV adopts large capacity lithium-ion battery which has long service life;

- The AGV adopts multiple protections which is intelligent and safe;